News

March 3, 2026

On January 28, the Baoshan High-tech Industrial Park held the "Pooling Efforts for High-tech Achievements and Embarking on a New Journey" Conference on optimizing the business environment. EVAPCO (Shanghai) Refrigeration Equipment Co., Ltd. was honored with the title of "Outstanding Enterprise with Exemplary Progress." This honor is not only a high recognition of EVAPCO's past achievements but also a full affirmation of its future development potential. EVAPCO has always adhered to innovation as its core principle, delving deeply into its specialized field and continuously enhancing the core

February 10, 2026

From January 27 (Tuesday) to January 30 (Friday), 2026, the 44th Heating, Ventilating, Air-Conditioning and Refrigerating Expo (HVAC&R JAPAN 2026) was held at East Exhibition Halls 4-6 of Tokyo Big Sight. It was fantastic to join forces with Dynatech to participate in the expo and share its highlights. During the event, we not only showcased our cooling tower units and delivered a dynamic presentation but, more importantly, also dived into some real discussions around high-efficiency equipment and solutions. At our booth, we engaged with industry partners and visitors, shared insights into our

January 15, 2026

As temperatures drop, it’s time to think maintenance! Checking your system now helps prevent downtime, costly repairs and spring start-up surprises. 1 2 3 4 5 For more details about maintenance and seasonal start-up, please refer to the specific equipment Operation and Maintenance Manual or contact the EVAPCO Mr. GoodTower® Service Center.

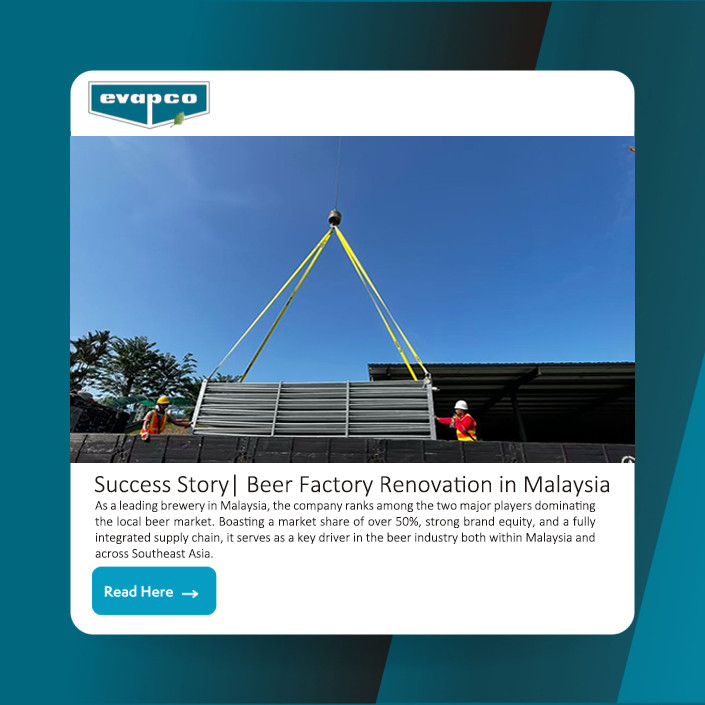

January 11, 2026

Evapco Mr. GoodTower Takes on Non-Evapco Equipment Malaysia Beer Plant Project ↑ As a leading brewery in Malaysia, the company ranks among the two major players dominating the local beer market. Boasting a market share of over 50%, strong brand equity, and a fully integrated supply chain, it serves as a key driver in the beer industry both within Malaysia and across Southeast Asia. Recently, EVAPCO carried out an upgrade and retrofit on non-EVAPCO equipment that had been in long-term operation at a major brewery in Malaysia. These three units serve on the beer production line. Their coils were

December 22, 2025

Thai Food Factory Renovation Striving for Excellence, Empowering the Future Four aging Non-Evapco cooling towers at a major Thai food processing plant were underperforming, with falling efficiency and rising energy use threatening production stability and cost management. The Mr. GoodTower service team collaborated closely with local Representative, deeply understand the customer's requirements. Through on-site inspections and measurements, we have successfully delivered a targeted, high-efficiency renovation plan that enabled rapid renovation! BEFORE AFTER severely scaled old fill ▲ The

December 8, 2025

Successful Application As a global innovator in heat transfer and cooling technologies, Evapco is committed to providing diversified, reliable solutions—even when faced with challenging or unexpected conditions on site. Recently, our Mr. GoodTower team was called in to support a customer whose non-Evapco unit suffered a critical drive system failure. With performance compromised and operations under pressure, the customer required a fast, effective replacement within a tight timeline. Here’s how Evapco delivered: 01 Engineering Expertise Without Disruption Our aftermarket engineering team

December 2, 2025

Establishing cooling through evaporation of water is a very common practice and the most effective method considering the available footprint and the initial investment. For some colder regions however this type of cooling comes with its own set of challenges. At certain ambient conditions the recirculating water will inevitably become too cold and may start to turn into ice. Through years of experience EVAPCO has established some basic guidelines which will allow you to operate your evaporative cooling equipment in a safe and secure manner. 1.When feasible go for a closed circuit solution

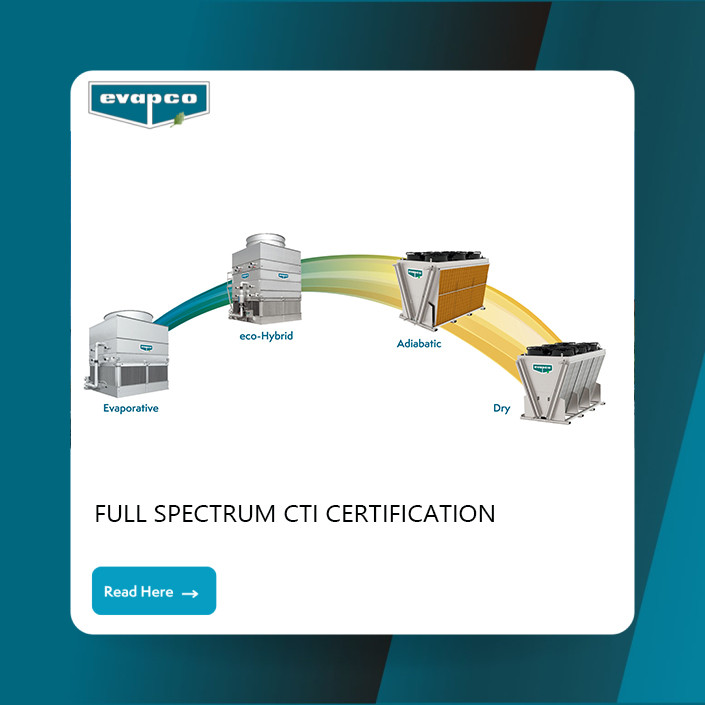

November 16, 2025

The Cooling Technology Institute (CTI) is globally recognized for performance validation of evaporative, hybrid and dry cooling equipment. EVAPCO is the only manufacturer that offers CTI certified heat rejection equipment ranging from fully evaporative all the way to dry and, currently, the only manufacturer with CTI certified dry cooler product lines. Overstating performance allows for manufacturers to provide customers with undersized equipment which can result in efficiency losses, higher utility consumption, and processes being put at risk of not meeting fluid temperatures at peak ambient

November 10, 2025

Time is money and, for industrial facilities and other critical infrastructure, downtime can lead to substantial loss of capital, angry customers, or even worse. It can stop product lines, leave workers in unsafe conditions, put hospital patients at risk, and, in the case of facilities like data centers, cause massive downstream headaches for an untold number of people. Read More: Costly Killer: How HVAC Contractors Can Reduce Downtime at Mission-Critical Facilities | ACHR News

October 30, 2025

The securities industry requires extensive real-time data exchange and continuous information communication, which place high demands on data center cooling solutions. Recently, Evapco’s aftermarket team successfully implemented a comprehensive cooling system upgrade for a leading securities firm in Shanghai, enhancing system reliability and securing uninterrupted data communication. Key features of the comprehensive cooling solution include: